Geometric Optimization for Value Engineering in Architectural Design

Summary of Impact

Many modern architectural projects involve large buildings with complex curved façades. Partitioning such complex shapes into façade panels is driven by aesthetic as well as economic concerns. Edges between panels form visible lines and if these are designed purely for aesthetics, most panels would have unique, distinct sizes, driving up costs and time. Prof Ajay Joneja's research focuses on shape modification, not only of the original architects’ surface, but also of the partitioning lines, minimizing panel variations while deviating minimally from the architects’ intent. His algorithms have been applied to buildings designed by Norman Foster, Frank Gehry, Zaha Hadid, Aedas and Bing Thom.

Underpinning Research

The rationalization of façade geometry is underpinned by two classical theoretical problems: clustering and approximation. We studied several aspects of these.

Rationalization of façade sub-frames - This research problem involves k-means clustering of the edges and joints. Façade panels of complex buildings are attached to its main structure via a sub-frame that can be modelled as a mesh of steel bars, or edges, connected at nodes, or joints. A classical approach to remesh the surface into near-isometric triangles is Centroidal Voronoi Tessellations (CVT). We developed an approach called KVT (K-means refinement of CVT) that uses a sigmoid model-based optimizer for controlled vertex perturbations, reducing the number of clusters of edges making up the mesh. By replacing individual links in the mesh with their cluster representative, we can significantly reduce fabrication costs of the supporting structures. On a curved surface, several edge clusters are required; hence, the angles of the edges incident upon any vertex also vary. Some roof meshes require the fabrication of several thousand joints; if many of these joints are nearly identical then the cost of fabricating the roof can also be significantly reduced. Given a design with a set of n distinct joints, the aim is to partition this set into the smallest number, k, of subsets, such that all joints in the same subset are identical to within a given tolerance. We developed an algorithm that (a) efficiently determines the angular disparity between a given pair of vertices, and (b) performs a remeshing that minimizes the number of unique joints. [R2][R6]

Optimization of quad-mesh façade units based on aesthetic constraints - Some façades of complex architectural projects are initially designed with free-form curved surfaces. These are fabricated out of a large set of simpler pieces, or tiles, that are more economical to manufacture and maintain. Architects often use a pattern of curves to yield an initial tiling that is then adjusted to improve the precise geometry of each tile. The quality of the adjustments is heavily impacted by the design created in the first stage (the focus of our research). Our proposed algorithm draped a pattern of aesthetic 2D-curves onto 3D-surfaces in order to create economically manufacturable tiling patterns. We tested our approach by using a common aesthetic curve, the Archimedean spiral. Examples from real-world projects illustrate the success of our method [R4][R5].

Approximation of façade surfaces by piecewise developable smooth surfaces - This type of surface approximation problem commonly arises in relation to the manufacturing of complex architectural surfaces and requires approximation of each facet of a surface subdivision by a simpler surface that is economical to fabricate. In addition to the approximation accuracy, the gaps between neighbouring panels must also be managed. Our team’s research demonstrates that the concept of shape features is useful in modelling such problems into a global optimization problem. When such non-linear optimization can be solved, it secures better solutions than the traditional two-stage method currently used [R1][R2][R3].

Details of the Impact

Supported by the Entrepreneurship Center in HKUST, Prof Joneja formed a company, Sane Form Ltd, in 2013. It specializes in the development and application of geometric optimization for the rationalization of architectural designs. Other principals in the company include Prof Joneja's former PhD student, Sai Kit Fan (whose research included work on rationalized re-meshing of architectural surfaces and on surface approximations), and two of his former MPhil students (who have actively worked on adopting the research of Sai Kit, X Wei [R3], [R5] and W Xiong [R6] on façade rationalization to develop application programs within a commercial CAD system, CATIA). In 2019 Sane Form employed ten engineers and one administrator; it has remained consistently profitable since inception. The company has worked on several landmark buildings across the world, where our research has been applied.

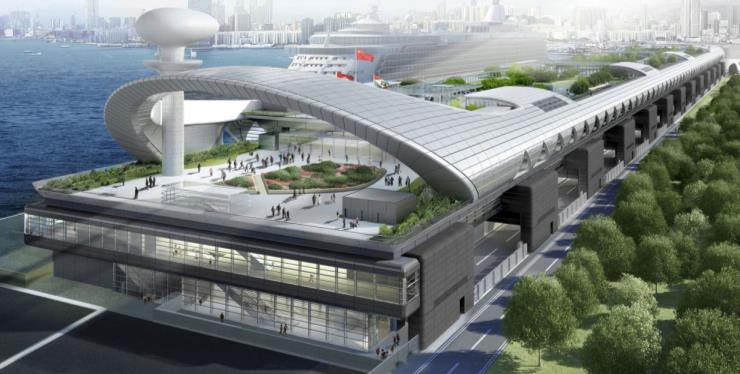

Kai Tak Cruise Terminal, Hong Kong. Architect: Norman Foster - In this project we applied our research on smooth piecewise developable strip approximations of curved surfaces, and our work on global optimization of sequences of parametric surfaces to minimize gap energy. Classical regression approaches can determine approximation of a surface by a single analytical surface. However, such approximations deviate unacceptably from the input surface. A better approximation is achieved via piecewise developable surfaces but the corresponding optimization formulation is not continuous, and therefore classical regression techniques fail.

Our research [R1][R4] provided a practical solution to this problem, reducing the cost of fabrication of façade panels by a factor of three. Furthermore, if a series of neighbouring surfaces (e.g. panels in a building) are independently approximated by developable surfaces, there may be large gaps along their shared edges. This is functionally and aesthetically unacceptable. A global optimization over the entire set of such panels allowed us to reduce the maximum gap significantly. We employed this approach to re-design the aluminium cladding panels along the eight lips of the Kai Tak Cruise Terminal with great success. Our research allowed cost effective fabrication of 160 lip panels, 1,144 window cladding panels, and 400 twisted panels in the CPA region of this building, covering over 8,000 m2 of the building.

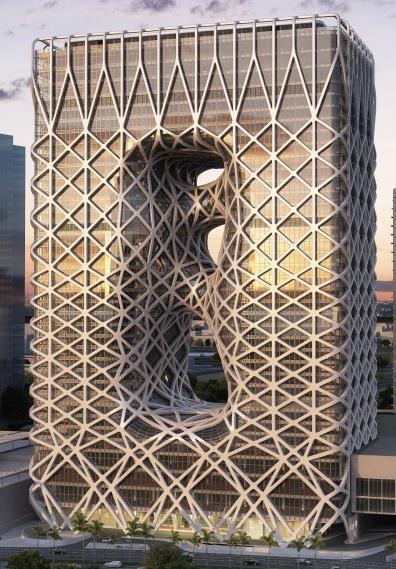

Morpheus Hotel, City of Dreams, Macau. Architect: Zaha Hadid - The Morpheus Hotel building is covered by an exoskeleton comprising a steel structure cladded in several thousand aluminium panels. Many of the panels (up to 6m2 in area) are non-developable. Our research enabled approximation by piecewise cylindrical surfaces, making them significantly cheaper to fabricate. Our algorithm also clustered the rolling curvature into a few groups, simplifying control of the rolling process. Research from [R1] and [R3] was used to find near-optimal surface partitions, and [R4] was used for approximation. A total of 6,000 exoskeleton cladding panels were processed by our software, with 960 panels requiring shape approximation. Similar processing was also employed on over 5,000 curved rails used to construct the sub-frame support.

XiQu Centre for performing arts, West Kowloon Cultural District, Hong Kong. Architects: Bing Thom, Ronald Lu - Our research on mesh rationalization [R2], [R5] and [R6] addresses the issue of reducing the variations in the façade sub-frame structure to reduce fabrication costs and complexity. A notable application of this research is the XiQu Centre for performing arts – a landmark building in the West Kowloon Cultural District in Hong Kong. The building's façade is made up rows of curved wings. Each wing is attached to the façade panels via three joints. To accommodate the varying orientation of the wings along the building, the 27,180 joints of the original design were clustered into 1,146 groups. Through rationalization using our technique, the optimized wing-orientation reduced the number of unique bracket types to 68. The optimization of the wing layout-curves over the entire building also resulted in a huge improvement in the sub-frame (allowing economical fabrication of 1,065 panels each with three interior stiffeners). The original design required transoms and stiffeners attached at varying angles to the back of the panel, whereas the design created using our technique simply required all stiffeners to be fixed orthogonal to the panel mullions. This change resulted in a saving of ~3% in the panel fabrication and assembly costs. Furthermore, the entire roof panelization of the XiQu Centre used a panel rationalization approach based on techniques we developed in [R5] and [R6]. Sane Form modelled the entire façade of the XiQu Centre: every visible external and internal façade surface of the building was modelled and optimized by our team.

References to the Research

[R1] Chen, M., Tang, K., Joneja, A., “Design of Developable Interpolating Strips,” Computer-Aided Design and Applications, v8, n4, 2011, p557-570

[R2] Fan, Sai Kit, Rationalized meshing of architectural surfaces. PhD thesis, HKUST, 2014

[R3] Wei X.Z., Joneja, A., Mount, D.M.M., “Optimal Uniformly Monotone Partitioning of Polygons with Holes,” Computer-Aided Design, 44 (12), 2012, p 1235-52

[R4] Fan, Sai Kit, Joneja, Ajay, Geometric optimization for developable panel approximation, Computer-Aided Design and Applications. 12(2), DOI: 10.1080/16864360.2014.962427, 2015

[R5] Wei, X, Zhao, B, Joneja, A, Xi, J, On the polygon containment problem on an isometric grid. IEEE Transactions on Automation Science and Engineering, v14(2), 1075–83, DOI: 10.1109/TASE.2015.2497372, 2017

[R6] Weidan Xiong, Pengbo Zhang, Pedro V Sander, Joneja, A, Shape-inspired architectural design. ACM SIGGRAPH Symposium on Interactive 3D Graphics and Games (I3D), Montreal, Quebec, Canada: 15–18 May 2018